Introduction of recommended articles

Technical information

Technical Guide Basic/Theory Edition

Description of features and function

- What is backflow prevention function? What is complete backflow prevention function?

- How to calculate the pull-up/pull-down resistance value inside the IC?

- What are ship function and shipping mode?

- What is ideal diode? What is the difference from discrete?

- What are differences among load disconnection, bypass, and Vout OR of step-up DC/DC

- What are power conversion efficiency and power supply efficiency? How is the efficiency measured?

- What are output voltage fixed products (Vout products) and output voltage externally adjusted products (FB products)?

- What are Nch open drain output and CMOS output?

- What is CL discharge (discharge function)?

- What kind of characteristics are the load-transient response and line-transient response characteristic?

- What is thermal shutdown/overheat protection?

- What is chip enable (CE function) and enable function (EN function)?

- What are pull-up and pull-down resistances? What is an unstable state?

- What are High voltage, Low voltage?

- What is a threshold?

- What is the soft start function and what is the difference from the inrush current prevention function

- What is The Under Voltage Lock Out (UVLO)?

- What are the characteristics of load stability and load regulation?

- Voltage Regulator Current Limiting Methods

DC/DC Converters

Voltage Regulators(VR)

Basics of Voltage Regulator

- What is a voltage regulator?

- Voltage regulator operation image

- Voltage regulator advantages and disadvantages

- Voltage regulator disadvantages: Loss and heat generation

- Deciding when to use voltage regulators or DC/DC converters

- Voltage regulator internal configuration

- Voltage regulator operation principles

Main Item and Characteristic of Voltage Regulator

Function of Voltage Regulator

Product Characteristics List/Comparison

Reset IC (Voltage detector / Watchdog Timer)

Basics of Voltage Reset IC (Voltage detector)

Features and Function of Reset IC (Voltage detector)

- Main characteristics of voltage detector : how to read SPEC - detect voltage / release voltage / hysteresis width

- Output current / ON resistance

- Release delay function

- Detection delay function

- Manual reset function

- Sense (VSEN) terminal separation function

- Function of voltage detector: unstable operation prevention function

- Function of voltage detector: hysteresis external adjustment function

Reset IC (Voltage detector) Design Edition

Technical Guide Design Edition

Design Support Tools

How to Use DC/DC Measured Electrical Characteristics Comparison Tool / Example of Use

How to Use Web DC/DC Simulation / Example of Application

- Characteristics / usage of Web DC/DC simulation

- Web DC/DC Simulation: confirmation of basic characteristics / comparison with observation result

- Web DC/DC Simulation: how to confirm the coil current under actual use conditions / how to select an optimum coil

- Web DC/DC Simulation: how to estimate the junction temperature

- Web DC/DC Simulation: How to confirm the switching frequency of PFM / switching current in between PWM and PFM

- Web DC/DC Simulation: calculation of maximum output current of step-up / inverter DC/DC converter

- Web DC/DC Simulation: maximum output current / efficiency giving consideration to battery impedance

- Web DC/DC Simulation: confirmation of efficiency and loss ratio / improvement of efficiency using loss ratio

Circuit/Solution Example

Circuit/Application Circuit Example(TIPS)

What is ideal diode IC?

Application Circuit Example (TIPS) : Peripheral Circuit Edition

Application Circuit Example (TIPS) : IC Edition

Application Solution Example

Application Solutions for Industrial Equipment/IoT

Power Source/Application-specific Solutions

- Primary Battery : Small and Low Consumption Solutions

- Li Rechargeable Battery : Small and Low Power Consumption Solutions

- Li Rechargeable Battery : Ultra-Small and Multi-Function Solutions

- 3.3V : Small Solutions for Multiple Power Rails

- 5V : POL Solutions for Multiple Power Rails

- 12V/24V, Li Multi Cell and 4 Dry Cell : LDO Solutions

- 12V/24V ~60V Input : Small Solutions

- 12V/24V : Multiple power rail solutions

- OR Connection Solutions for Backup and Multiple Power Sources

- LTO Battery : Solutions for Sma ll and Low Consumption Devices

- Solutions for Energy Harvesting

- Compact and Space Saving Power Supply Solutions

- Charging using the charging box/charging stand Power solutions for wearables, TWS and hearing aids

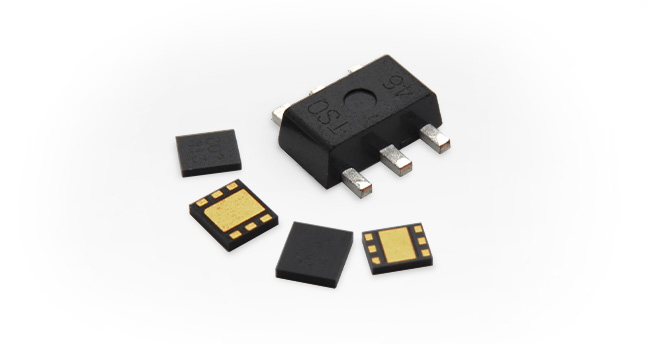

- Low Profile Power Supply Solutions for h=0.33mm/0.40mm max.